Individual stamping and forming.

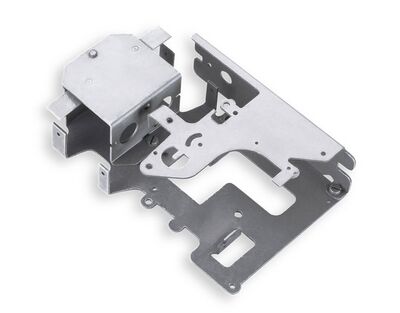

Top quality punches and dies are the preferred choice when high volumes or repetition rates are required. As such your die, carrying your brand name, company logo or your type designation produced to your specification. Whether sunken or raised embossing is purely a matter of design.

Dependent on the material used, a variety of type fonts are possible. Sequential numbering tools offer additional necessary individuality, e.g., asset tags, cloakroom tags, vehicle identification plates or engine block plates.

Our expertise in embossing and stamping identification plates

Machine resources

We maintain stamping and hydraulic presses for material thicknesses of 0,1 mm – 10 mm. For your low volume orders we maintain a wide range of single load presses. Stamping presses with speeds up to 300 SPM and 800 kN press force. Eccentric presses with a speed of 100 strokes per minute at 2,500 kN pressing force. Hydraulic presses of 30 SPM and 2500 kN press force.

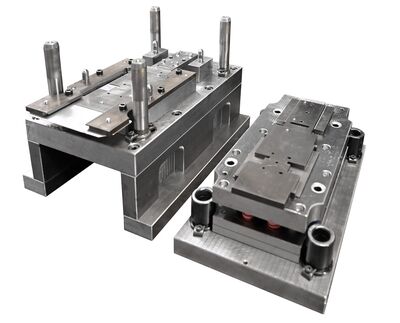

Tool design

In-house manufacture of tools, dies and complex progressive tooling. Highly skilled toolmaking forms the basis of reliable manufacture of your product.

- Highly skilled toolmaking

- Pre-supplied tools accepted

- Preventive maintenance and storage of your tools

Service and assembly

We manufacture to your specification. If you wish to supply your own tools and dies or supply free issue materials needed for production. We can accommodate you. If you wish, we can also do further mechanical operations and/or the surface treatment.

- Subsystem assembly

- Completion and packaging

- Logistics and shipment

- Tool & Die design

- Surface treatment

- Mechanical processing